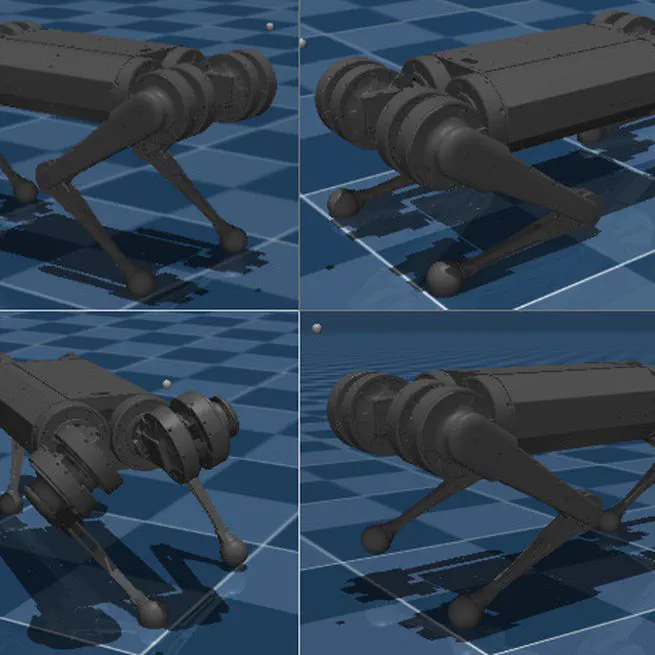

MPC Trotting Controller for Quadruped Robot

Walking controller for quadruped robot.

Dec 9, 2025

Vivo Guide Dog Robot

A custom quadruped robot for guiding blind and low-vision individuals.

May 30, 2025

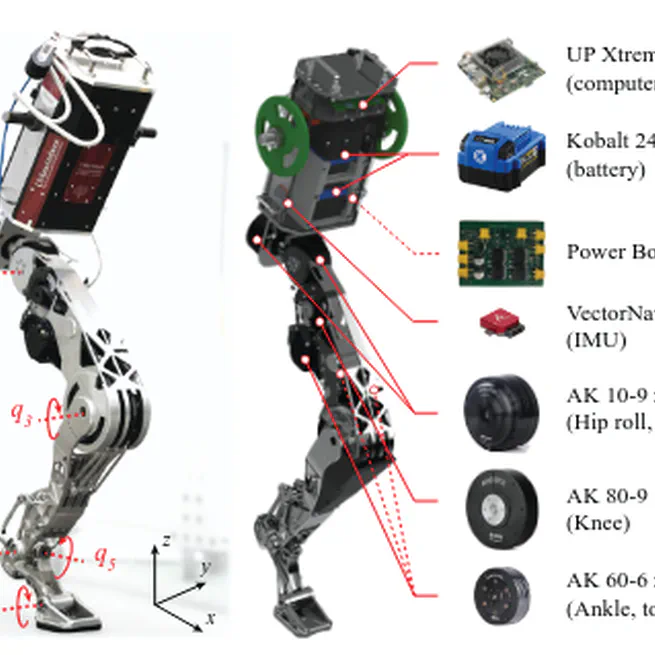

StaccaToe (Single-Legged Hopping Robot)

A single legged hopping robot with toe actuation.

Oct 14, 2024

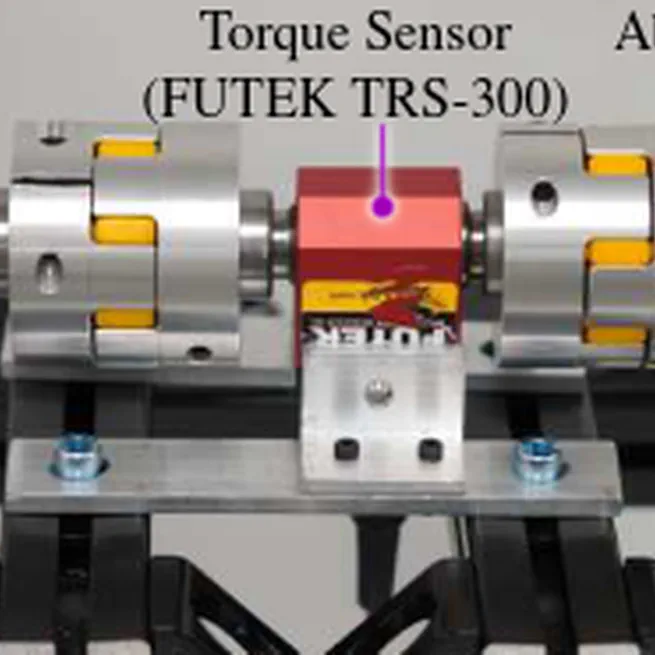

Dynamometer

Measures output characteristics of BLDC motors.

Oct 14, 2024

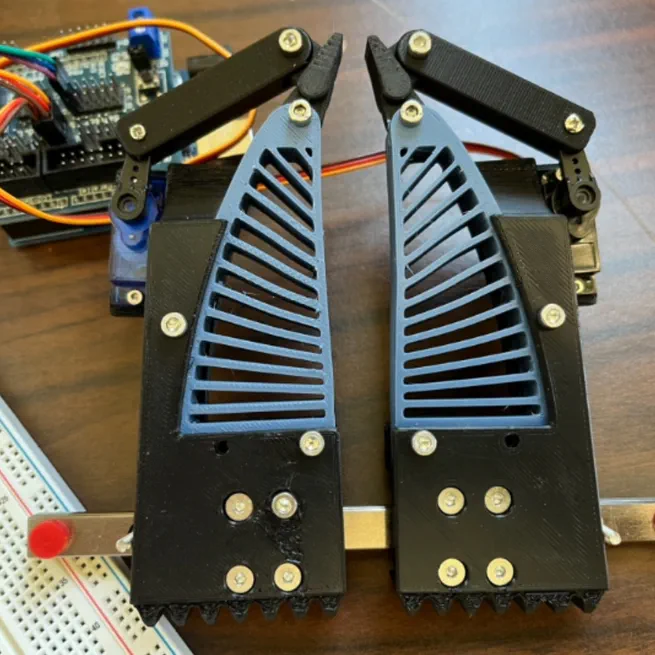

Soft Gripper with Rigid Finger Tips

Gripper for both power grasps and pinching.

May 10, 2024

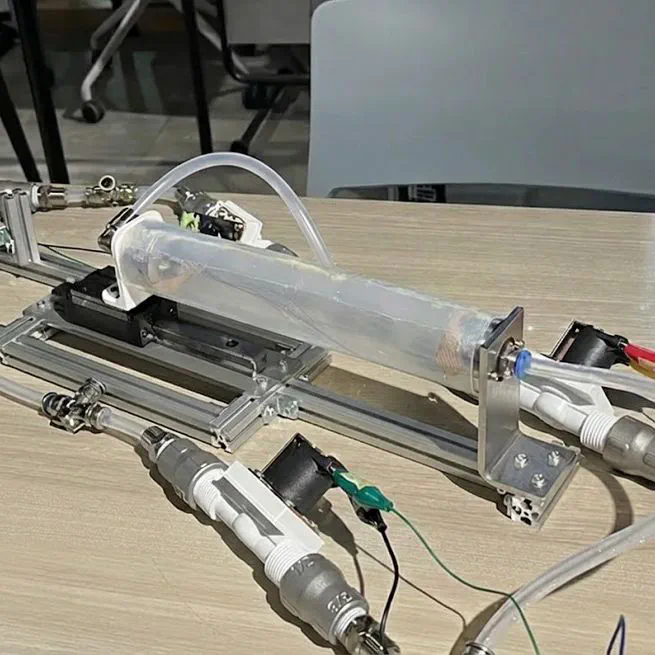

Shape Memory Alloy Actuator Test Bed

An SMA actuator controlled by temperature controlled water.

Oct 24, 2023